Guide to Quality in Analytical Chemistry - 4th edition (2026)

- Details

- Published: Friday, 06 February 2026 15:24

Content

The aim of this guide is to provide laboratories with guidance on best practice for the analytical operations they carry out. The guidance covers both qualitative and quantitative analysis carried out on a routine or non-routine basis.

The aim of this guide is to provide laboratories with guidance on best practice for the analytical operations they carry out. The guidance covers both qualitative and quantitative analysis carried out on a routine or non-routine basis.

This 4th edition is a revision of the CITAC/Eurachem Guide published in 2016. This revision reflects changes that were introduced with the publication of the 2017 version of ISO/IEC 17025.

The Guide focuses on the requirements of ISO/IEC 17025, however the content should also be of use to organisations seeking accreditation or certification against the requirements of standards such as ISO 15189 or ISO 9001, or compliance with the Principles of Good Laboratory Practice. The Guide will also provide useful information both for laboratories that wish to establish a quality management system but are not seeking formal recognition, and for those involved in education and training.

Availability

You may download the guide from this website at no cost.

- Download the guide in English [pdf, 1.6 Mb] (2026-02-06]+

+ Dates of publication on this site

Translations

Translation into other languages is permitted for members of Eurachem. Other offers of translation should be directed to the Eurachem Secretariat for permission. The Eurachem policy on maintenance and development of Eurachem guidance, available on the Policies page, gives further information on translation.

Publication date

This third edition was approved for publication in January 2026 and first published on this website on 6th February 2026.

Citation

This publication should be cited* as: “V. Barwick and K. C. Tsimillis (Eds), Eurachem/CITAC: Guide to Quality in Analytical Chemistry: An Aid to Accreditation (4th ed. 2026). ISBN 978-0-948926-40-2. Available from www.eurachem.org

*Subject to journal requirements

Previous editions

The third edition of this Guide, and earlier editions, can be found in the publication archive on this website.

Guidance is given on how to validate a measuring procedure that includes the primary sampling (VaMPIS). It is a supplement to existing Eurachem guidance on “The Fitness for Purpose of Analytical Methods” and “Measurement Uncertainty arising from Sampling”. The overall aim is to extend the concept of ‘validation of a measurement procedure’ beyond the validation of the analytical method (or procedure) alone, in order to include the primary sampling (and physical sample preparation) within the validation process.

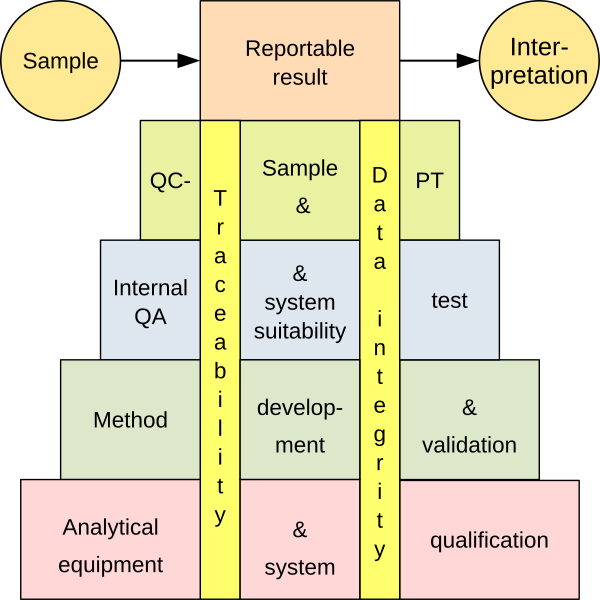

Guidance is given on how to validate a measuring procedure that includes the primary sampling (VaMPIS). It is a supplement to existing Eurachem guidance on “The Fitness for Purpose of Analytical Methods” and “Measurement Uncertainty arising from Sampling”. The overall aim is to extend the concept of ‘validation of a measurement procedure’ beyond the validation of the analytical method (or procedure) alone, in order to include the primary sampling (and physical sample preparation) within the validation process. A wide variety of analytical equipment is used in analytical laboratories, ranging from simple apparatus to complex computer-based systems, to collect data that helps to obtain a reportable result. Many of these pieces of equipment combine a measurement function with software control. There are many ways to demonstrate that an equipment is qualified and under control, including qualification, calibration, validation and maintenance. To ensure ‘fitness for purpose’, an integrated approach based on risk assessment is recommended.

A wide variety of analytical equipment is used in analytical laboratories, ranging from simple apparatus to complex computer-based systems, to collect data that helps to obtain a reportable result. Many of these pieces of equipment combine a measurement function with software control. There are many ways to demonstrate that an equipment is qualified and under control, including qualification, calibration, validation and maintenance. To ensure ‘fitness for purpose’, an integrated approach based on risk assessment is recommended.

Many decisions with socio-economic or individual impact depend on qualitative analysis, including decisions related to food safety, clinical diagnosis, and forensic evidence, are based primarily on qualitative, rather than quantitative, chemical analysis. Qualitative analysis is analysis that returns a classification rather than a numerical value, such as the identity of a chemical substance, the type of plastic of a microparticle, the potential source of an oil spill, the presence of a banned sports doping substance, or the presence of accelerant in fire debris. Sometimes, such classifications rely solely on qualitative tests; others may use measurement results (such as line frequencies in a spectrum) to reach a conclusion.

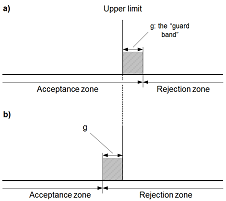

Many decisions with socio-economic or individual impact depend on qualitative analysis, including decisions related to food safety, clinical diagnosis, and forensic evidence, are based primarily on qualitative, rather than quantitative, chemical analysis. Qualitative analysis is analysis that returns a classification rather than a numerical value, such as the identity of a chemical substance, the type of plastic of a microparticle, the potential source of an oil spill, the presence of a banned sports doping substance, or the presence of accelerant in fire debris. Sometimes, such classifications rely solely on qualitative tests; others may use measurement results (such as line frequencies in a spectrum) to reach a conclusion. In order to decide whether a result indicates compliance or non-compliance with a specification, it is necessary to take into account the measurement uncertainty associated with the result. This guide provides guidance on how uncertainty may be taken into account in deciding compliance with a limit.

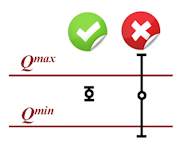

In order to decide whether a result indicates compliance or non-compliance with a specification, it is necessary to take into account the measurement uncertainty associated with the result. This guide provides guidance on how uncertainty may be taken into account in deciding compliance with a limit. Blanks are an important tool and are used in the determination of most performance characteristics during a validation process. They are also often included in each analytical run during routine use of the measurement procedure. There are many different types of blanks and the analyst must consider which blanks to include during preparation of the validation plan.

Blanks are an important tool and are used in the determination of most performance characteristics during a validation process. They are also often included in each analytical run during routine use of the measurement procedure. There are many different types of blanks and the analyst must consider which blanks to include during preparation of the validation plan. Planning is an essential stage in the validation process. Before starting any experimental work, the aim should be to have a clear plan for the entire validation study. This should cover the performance characteristics that will be studied, the target value for each performance characteristic, the materials that will be analysed, the level of replication and order of the experiments, any statistical analysis that will be used, and how the method will be judged as being fit for purpose.

Planning is an essential stage in the validation process. Before starting any experimental work, the aim should be to have a clear plan for the entire validation study. This should cover the performance characteristics that will be studied, the target value for each performance characteristic, the materials that will be analysed, the level of replication and order of the experiments, any statistical analysis that will be used, and how the method will be judged as being fit for purpose. This guideline is applicable to analytical fields where the target uncertainty is not set by the regulator or the client, or where a minimum difference of the studied parameter in the same or different items must be detected in R&D work. This guide discusses how to set the target uncertainty for process development and for applied or fundamental research using information about the smallest difference or system trend that must be distinguished in a reliable way.

This guideline is applicable to analytical fields where the target uncertainty is not set by the regulator or the client, or where a minimum difference of the studied parameter in the same or different items must be detected in R&D work. This guide discusses how to set the target uncertainty for process development and for applied or fundamental research using information about the smallest difference or system trend that must be distinguished in a reliable way.